- Laman

- >

- produk

- >

- VCI Masterbatch pekat

- >

VCI Masterbatch pekat

1. Masterbatch VCI Bebas Nitrit DM-130N ialah masterbatch plastik antirust putih atau kuning muda yang dihasilkan melalui penyemperitan resin poliolefin, VCI dan bahan tambahan lain.

2. VCI Master Batch ialah Resin jenis Selamat.

3. VCI Master Batch lulus REACH, SGS, REACH.

- CVCI

- China

- 5 hari selepas pembayaran

- 500 tan sebulan

- maklumat

- Video

- Download

Product description of VCI Master Batch:

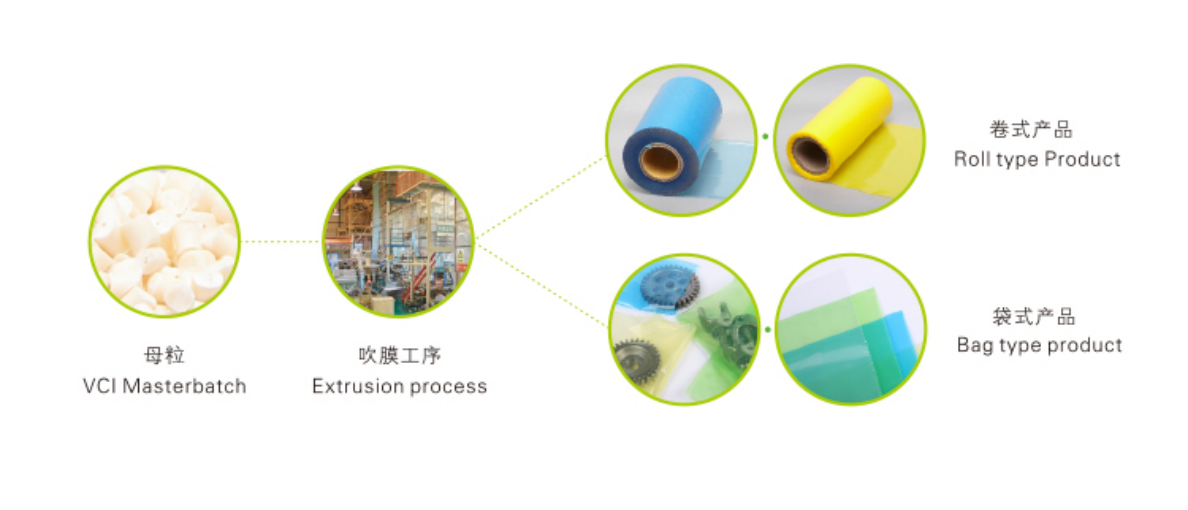

Nitrite Free VCI Masterbatch DM130N is a yellowish anti-rust plastic Corrosion Inhibitor VCI Master Batch made by mixing polyolefin resin, vapor phase corrosion inhibitor and other additives through extrusion. It is mainly used in the production of vapor phase anti-rust plastic film products. VCI Concentrate is a concentrated version of 130 VCI Master Batch with a very low addition ratio. It is a cost-effective multi-metal anti-rust VCI Concentrate.

Product model: SF/DM-130N

Product features of Corrosion Inhibitor:

1. Nitrite Free VCI Masterbatch addition ratio is low. Suitable for a variety of metal anti-rust packaging.

2. Nitrite Free VCI Masterbatch extrusion blow molding process is simple to operate and can be produced with ordinary film blowing equipment.

3. VCI Masterbatch can add color masterbatch, antioxidant, flame retardant and other functional masterbatch as needed during the production of gas phase anti-rust plastic film products.

VCI Master batch application range:

Corrosion Inhibitor VCI Concentrate is applicable to metals including iron, cast iron, copper and copper alloys, aluminum and aluminum alloys, stainless steel, aluminum alloys and other metals. Corrosion Inhibitor is applicable to the extrusion blow molding of vapor phase rust-proof plastic film products, vapor phase rust-proof heat shrinkable film and vapor phase rust-proof pearl cotton. The application of other anti-rust plastic products needs to be determined by the process.

Notes of VCI masterbatch:

1. Corrosion Inhibitor VCI Master Batch base resin: Please use blown film grade low-density polyethylene resin, medium-density polyethylene resin, linear low-density polyethylene resin.

2. Recommended Corrosion Inhibitor VCI Master Batch addition ratio: 2% of the anti-rust layer (can be increased or decreased according to customer anti-rust performance requirements).

3. VCI Concentrate blown film temperature: extrusion blow molding processing temperature is lower than 185℃.

4. When producing anti-rust film, the working environment should be kept ventilated and dry. If VCI Concentrate is found to be damp, it should be dried at 50℃ for 90 minutes.

5. The remaining VCI Masterbatch should be re-packed in moisture-proof packaging for standby use.

6. Packaging and storage: cardboard barrel packaging, 20 kg/barrel, or agreed packaging. VCI Concentrate should be stored in a cool and dry place, away from direct sunlight, fire sources and pollutants. Sealed storage, shelf life 12 months.

FAQs of VCI Concentrate:

Q: What is Corrosion Inhibitor VCI Concentrate?

A: VCI Master Batch is a functional masterbatch containing a high proportion of active rust-inhibiting ingredients. It is used for mixing with plastics for extrusion or blown film, imparting long-lasting rust-proof properties to packaging materials.

Q: Why choose a concentrated version VCI masterbatch over a standard version?

J: Masterbatch VCI pekat memerlukan nisbah penambahan yang lebih kecil untuk mencapai kesan kalis karat yang sama, menjimatkan kos sambil memastikan sifat fizikal produk plastik yang stabil.

S: Apakah kaedah pemprosesan yang sesuai untuk Masterbatch VCI Bebas Nitrit?

A: VCI Concentrate boleh digunakan dalam pelbagai teknik pemprosesan plastik, termasuk filem tiupan, pengacuan suntikan, dan filem tuang. Ia amat sesuai untuk pengeluaran filem VCI, beg kalis karat, dan penutup kalis karat.

S: Apakah langkah berjaga-jaga yang perlu diambil apabila menggunakan VCI Master Batch?

J: Adalah disyorkan untuk mencampurkan terus dengan resin asas mengikut nisbah yang disyorkan tanpa bahan tambahan tambahan. Elakkan pendedahan berpanjangan kepada suhu tinggi untuk mengekalkan aktiviti bahan kalis karat.

S: Apakah industri yang digunakan terutamanya oleh VCI Master Batch?

J: Masterbatch VCI Bebas Nitrit digunakan secara meluas dalam pembungkusan kalis karat untuk keluli, bahagian automotif, jentera, komponen elektronik dan aplikasi lain. Ia amat sesuai untuk pelanggan yang memerlukan penyimpanan jangka panjang dan penghantaran laut.

Sijil Produk dan Syarikat:

CVCI telah menerima lebih 40 anugerah di peringkat wilayah dan kementerian dan ke atas, meliputi inovasi teknologi dan pencapaian produk. Majoriti anugerah ini berkaitan dengan produk teras seperti kertas anti-karat, minyak anti-karat, dan Pekatan VCI Perencatan Kakisan. Anugerah ini bukan sahaja mewakili pengiktirafan kerajaan dan industri terhadap CVCI, tetapi juga menunjukkan keberkesanan cemerlang penyelesaian anti-karat kami dalam aplikasi praktikal, benar-benar menyelesaikan cabaran pelanggan.

Tentang kami:

Ditubuhkan pada tahun 1989, CVCI telah memberi tumpuan kepada perlindungan permukaan selama 33 tahun. Ia adalah perusahaan teknologi tinggi negara yang mengkhusus dalam perkhidmatan penyelidikan, pembangunan, pembuatan dan aplikasi bahan perlindungan anti-karat logam, terutamanya VCI Concentrate fasa wap. Kami adalah yang pertama dalam industri yang lulus pensijilan sistem ISO9001 dan ISO14001.